Dimensions of Regular Sheets

|

|

Designation

|

Dimensions

|

A0

|

841

mm x 1189 mm

|

A1

|

594

mm x 841 mm

|

A2

|

420

mm x 594 mm

|

A3

|

297

mm x 420 mm

|

A4

|

210

mm x 297 mm

|

A5

|

149

mm x 210 mm

|

The size of drawing board: 45x60cm/60x75cm

- The largest permissible size for a dimension is known as upper limit

- Plan section specification is necessary for making an estimate

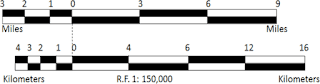

- Representative fraction (RF) is defined as Length of an object in the drawing / Actual length of the object

- In an aligned system of dimensioning, the dimension may be read from Bottom or right hand edges.

- Comparative scale is a pair of scale having a common length of scale

- Hatching line are drawn at 45° to reference line

- Method of surveying considering Geometric survey.

Beam Compass - A beam compass is a compass with a beam and sliding sockets or cursors for drawing and dividing circles larger than those made by a regular pair of compasses.

A bow compass capable of drawing the smallest possible circles

- Drop Compass for Small Circles up to 29mm diameter

- Tube with Replacement Leads

- All Metal Quality German made Instrument

An angle can be set off and measured with the help of scale of chords

Circle Perimeter = π x D

π = Perimeter/Diameter = 3.14159

Diagonal scale is an engineering measuring instrument which is composed of a set of parallel straight lines which are obliquely crossed by another set of straight lines. Diagonal scales are used to measure small fractions of the unit of measurement.

✓ The sum of any two side of triangle is greater than the third side

✓ A right angle triangle revolving about its perpendicular side forming Cone solid

- sketch puts more focus on the face or front of an object

- sketches are usually drawn using a 45 degree angle to render the 3rd dimension

Isometric projection

- Sketches puts more focus on the edge of an object.

- sketches are drawn using a 30 degree angle

- In perspective drawings Plane of projection/ picture plane is placed between the observer and the object

- In an orthographic projection the rays are assumed to be parallel

Parallel perspective:

linear perspective in which parallel lines of the object that are perpendicular to the drawing surface are represented as meeting at a point on the horizon in line with the common point of intersection of the lines of projection.

One-point perspective is also known as Parallel perspective.

Angular perspective:

An object's vertical lines do not relate to the perspective rules of the horizontal lines. By changing the vanishing points of the object, one can make increase or decrease the size of the object.

Two point perspective is also known as Angular perspective.

The distance a screw thread advances axially for one complete revolution is called Lead

Square thread is using for mechanical screw jack.

Rag bolt is a Foundation bolt

AutoCAD comments

OOPS – Retrieve the deleted item

DDLMODES – Set new layer

AECTOACAD - ExportToAutoCAD

AA - AREA

AL - ALIGN

Tangential keys are used when very high torque of impact type to be transmitted in both direction of rotation

M30 x 2 for a bolt represents _ Metric threads of 30mm outside diameter and 2mm pitch.

The washer is specified by inner diameter

Wing nuts are used in light duty assembly which require frequent removal or fixing.

✓ In a riveted joint the tensile, shearing and crushing stresses are based on the diameter of drilled hole

✓ A welded joint as compared to riveted joint, has more strength

Units

Pressure – Bar

Energy / Work – Joule

Power – Watt

Top 10 Materials with Highest Melting Point in the World

1) Tantalum Hafnium Carbide Alloy (3990℃)

2) Graphite (3652 ℃)

3) Diamond (3550 ℃)

4) Tungsten (3400 ℃)

5) Titanium Boride (3225℃)

6) Zirconium boride (3245℃)

7) Rhenium (3180℃)

8) Titanium Carbide (3100℃)

9) Osmium (3045℃)

10) Silicon Carbide (2820℃)

The ratio of the pitch diameter to the number of teeth of the gear is called Module

The profile of a gear tooth is in the form of Involutes

The size of the gear is usually specified by pitch circle diameter

✓ The point of contact of two pitch circles of mating gears is called Addendum

✓ The radial distance of the tooth below pitch circle is called Dedendum

Bench vices, also known as woodworking or engineer's vices

The box nut of a bench vice is made of Phosphorus bronze

The vice clamps are used to protect the finished surfaces

The size of an engineer’s vice is specified by the width of the jaw

Leg vice is using for forging works

Toolmaker vises are precision ground on all four sides

Rasp cut file is used for filing wood File grade determined by spacing of teeth

✓ The term surface finish refers to the Roughness or smoothness of a surface

✓ The files are made of high carbon steel

✓ A Second cut file is used for bringing the jobs close to the finishing size.

The Mallet hammer made of wood

The portion of the hammer which is not hardened is the Cheek

Four common types of cold chisels.

· Flat chisel, the most widely known type, which is used to cut bars and rods to reduce surfaces and to cut sheet metal that is too thick or difficult to cut with tin snips

· Cross cut chisel is used for cutting grooves and slots. The blade narrows behind the cutting edge to provide clearance.

· Round nose chisel is used for cutting semi-circular grooves for oil ways in bearings.

· Diamond point chisel is used for cutting V shaped grooves

The chisel will dig into the material when the angle of inclination is more

A slight convexity is given to cutting edge to prevent digging on the ends.

The process of beveling at the end is calling Counter boring

· Vernier caliper- Least count 0.1 mm

· Vernier metric micrometer - Least count 0.001 mm

· Screw gauge/ metric micro meter - Least count 0.01 mm

· Vernier bevel protractor – Least count 5 minute (1°/12)

· Vernier height gauge - Least count 0.02mm

A sine bar is used for finding the angle of a taper job

Drilling Machine

Pneumatic hand drilling machine operated by air or gas under pressure

A service petroleum pipe line flange is to be drilled, we will choose Pneumatic hand drilling machine

Electrical hand drilling machine

The purpose of Dressing is to restore the cutting action of the grinding wheel

Sensitive drilling machine

The drift is used for drilling machine is removing the drill from the machine spindle

Soluble oil is the suitable cutting fluid for drilling mild steel

The point angle of standard drill is 118°

Drill size for 10mm reamer is 9.75mm

· The distance, which the cutting edge of a tool passes over the material in a minute, while machine is known as Cutting speed

Jigs and Fixture

The jig is used for guiding the cutting tool (like a drill bit), a fixture never comes into direct contact

with the cutting tool

The production of flat vertical surfaces on both sides of a workpiece is called Straddle milling

Gang milling is the term applied to an operation in which two or more milling cutters are mounted on the same arbor and used when cutting horizontal surfaces. All cutters may perform the same type of operation or each cutter may perform a different type of operation.

End milling is the most versatile form of milling that can be used to machine slots, shoulders, die cavities, contours, and profiles. An end milling process consists of a cylindrical cutter that has multiple cutting edges on both its periphery and its tip.

Form milling is the process of machining special contours composed of curves and straight lines, or entirely of curves, at a single cut

A single angle milling cutter is used for angular surfaces, such as chamfers, serrations, and grooves.

The lathe bed is made of Grey Cast Iron

Four jaw chuck is using for clamping irregular shaper work on lathe

A lathe dog, also known as a lathe carrier, is a device that clamps around the workpiece and allows the rotary motion of the machine's spindle to be transmitted to the workpiece. A carrier is most often used when turning between centers on a lathe, but it may be used on dividing heads or any similar situation.

A lathe faceplate is a basic work holding accessory for a wood or metal turning lathe. It is a circular metal plate which fixes to the end of the lathe spindle.

In a lathe machine internal and external taper turning can be done by swivelling the compound slide

✓ When a tool is set above the center line of lathe the front clearance decreases

The ability of a tool material to resist shock or impact forces is known as Toughness

Wear resistance is defined as the ability of stone to resist comprehensive external forces such as abrasion, edge cutting and impact etc.

Material hardness is the property of the material which enables it to resist plastic deformation or the ability of a metal to cut another metal.

The term machinability refers to the ease with which a metal can be cut (machined) permitting the removal of the material with a satisfactory finish at low cost.

Discontinuous chips tends to be formed when one or more or the following conditions exist:

1. Brittle material, such as cast iron and bronze.

2. Large chip thickness

3. Low cutting speed

4. Small rack angle

✓ If the metals are ductile and cutting speed are high, then continues chips are formed

✓

The part of the Universal surface gauge the Guide pin will helps to draw the parallel line along the datum edge

The reference surface during marking is provided by marking table surface

Electro discharge machining (EDM) process also known as spark machining

Slitting Machine is using for cutting a sheet of material in a straight line along the length

Embossing machines cut materials such as thin plastic into certain shapes, foam, paper, and fabric.

Perforators are commonly used for creating coupons

The punching marks on the lines drawn during marking off are known as Witness marking

✓ In honing process, the movement of spindle is Vertical & reciprocating.

➢ In acetylene cylinder, the acetylene is dissolved in Acetone

➢ In Foundry, Oil sand is used for making cores

Farad is the unit of capacitance

Henry is the unit of inductance

Coulomb is the unit of Electric charge

The SI unit of electrical resistance is the ohm (Ω)

Siemens is the unit of Electrical resistance and conductance

Compound Wound Generator

A compound generator or Compound wound generators have both series field winding and shunt field winding. One winding is placed in series with the armature, and the other is placed in parallel with the armature

Shunt generator

A shunt generator is a type of direct current electric generator in which field winding and armature winding are connected in parallel

Series wound generators

When the field winding of a DC generator is connected in series with the armature

· In automotive usage, scavenging is the process of pushing exhausted gas.

· The loud pulsating noise heard within the cylinder of an IC engine is known as Detonation

· Super charging is the process of increase the pressure of air by using compressors

· Mechanical efficiency is the ratio of break power to the indicated power of an IC engine

· Brake Thermal Efficiency is defined as break power of a heat engine as a function of the thermal input from the fuel.

· The relative efficiency of an I. C. engine is the ratio of the indicated thermal efficiency to the air standard efficiency

· Indicated thermal efficiency is define as the ratio of the indicated power of the engine to the fuel power.

The Thermostat is a metallic capsule containing a material that expand with heat such wax (or they also use liquid alcohol because when it evaporates its volume expand also). The role of the thermostat is to maintain the circulation of water inside of the engine block when the engine is started in a cold state in a manner that the normal functioning temperature of the engine is attended quickly. After reaching this temperature (about 80 °C), the water's temperature continue to increase so that the thermostat expand and open progressively the valve permitting the water to flow in the radiator for cooling.

· In an IC engine the thermostat is essential component in the Cooling system

Internal Combustion Engine

·

The irregularities in the surface texture due to the inherent action of production process is called Roughness

Roughness values

Scotch yoke mechanism is an inversion of double slider crank chain mechanism

Old harm coupling is used for while two shaft axis are parallel but not in same alignment.

Muff coupling is used for while two shaft axis are parallel and in same alignment.

Flange coupling is used for while two shaft axis are parallel and in same alignment. And heavy torque transfer

Sleeve coupling is the simplest type of rigid coupling.

The portion of the shaft carried in the plane bearing is often referred as Journal

The external threads on G.I pipes are cut easily by Dies and die stocks

UCS – Universal Co-ordinate System

Polar Co-ordinate system is mostly used in AutoCAD for Angular lines

AutoCAD Function Keys

· F1 – Help

· F2 – Comment box

· F3 – Osnap

· F4 – 3DOsnap

· F5 – Isoplane

· F6 – Dynamic UCS

· F7 – Grid

· F8 – Ortho

· F9 – Snap

· F10 – Polar

· F11- Object Snap Tracking

Solder is an alloy of Lead and Tin

Pressure energy is stored in a hydraulic accumulator

✓ The Fast pulley is a pulley which has fitted on the shaft

✓ The Loose pulley runs freely on the shaft, it takes care of the idling time and does not transmit any power.

✓ The pulley for flat belt is generally made convex and this is called Crowning

✓ The actual difference caused between the surface speed of the belt and pulley is called Slip

✓ In V belt specification, c3048 IS:2494, 3048 means Nominal inside length in mm

The threads provided on standard pipe fittings are British Standard Pipe (BSP)

Turpentine oil is used as thinner

Dwell period of a cam the follower does not move

Reciprocating pump is suitable for high head and less discharge

Cam clamps are used for holding small pieces where you don't need much pressure

Wedge clamp works on the principle of inclined planes

Toggle clamp has a single clamping plate and is designed to hold a workpiece down on a work surface, such as a bench top. The clamp uses a fast-action mechanism

Latch Clamps is for applications where heavy duty Latch type clamping

Feeler gauge

A gauge consisting of a number of thin blades for measuring narrow gaps or clearances.

It is used to check the gap between the matching parts.

Snap gage

A snap gage is a form of go/no go gauge. It is a limit gage with permanently or temporarily fixed measurement aperture which is used to quickly verify

Plug gages

Plug Gauges are measurement tools used for checking diameters of inside and outside, threads, grooves, cones, key ways, and chamfers.

✓ A plug gauge which has its ‘Go’ and ‘No Go’ sizes on the same end is known as Progressive type plug gauge.

Clinometer is using for sensitive angle measuring

In pneumatic system, a sensor serves the purpose of Feedback

Factor of safety

The ratio of ultimate stress to the working stress

Poisson's ratio

The ratio of Lateral strain to linear strain

Bulk modulus

The ratio between direct stress and volumetric strain

Modulus of Rigidity

The ratio of shear stress to the displacement per unit sample length (shear strain)

Young’s modulus

Young’s modulus (Y) is the ratio of the tensile/compressive stress (σ) to the longitudinal strain (ε).

✓ Compressive stress is formed when the section is subjected to axial pushes

✓ A cantilever beam having uniformly distributed load on the entire length, then the maximum bending moment will be at the fixed end

When one of the links of a kinematic chain is fixed, then the chain is called mechanism

The act of joining together slip gauges is termed as Wringing

Kaplan turbine is an axial flow reaction turbine

Circlips are made of spring steel

While cutting small diameter pipe, it is advisable to watch regularly and ensure that More saw teeth are in contact

Hacksaw blades are made of Low alloy steel and high speed steel

Scribers are made of High carbon steel

In brass the percentage of Copper and Zinc is 60, 40 respectively

In Bronzes the percentage of Copper and Tin is 88, 12 respectively

Invar is the alloy by mixing 64% of iron and 36% of nickel

Babbitt is the alloy by mixing 89% Tin, 9% Antimony and 2% Copper

The process of introducing carbon into low carbon steel in order to produce a hard surface is known as Carburizing

✓ Material which do not contain iron is known as Non-ferrous metals

✓ A chemical compound of carbon with iron is called Cementite

✓ The best primer used for structural steel work is Red lead

Pig iron refined in a cupola furnace produces Cast iron

Wrought iron is produced by Pudding process

The Bessemer process was the first inexpensive industrial process for the mass production of steel from molten pig iron before the development of the open hearth furnace

Open hearth furnaces are one of a number of kinds of furnace where excess carbon and other impurities are burnt out of pig iron to produce steel.

✓ A grain structure is defined in hot working process

Radiation is the process of heat transfer from hot body to cold body without effecting the medium.

Conduction is the process by which heat or electricity is directly transmitted through the material of a substance when there is a difference of temperature or of electrical potential between adjoining regions, without movement of the material.

Convection is the movement caused within a fluid by the tendency of hotter and therefore less dense material to rise, and colder, denser material to sink under the influence of gravity, which consequently results in transfer of heat.

An adiabatic process occurs without transfer of heat or mass of substances between a thermodynamic system and its surroundings.

✓ A process which is adopted to make the steel soft called Annealing

The purpose of given heat treatment is

· To relieve internal stress

· To improve machinability

· To refine grain size

· To soften the material

· To increase resistance to wear and corrosion

· To improve ductility and toughness

· To cut miscellaneous metal

· To change the chemical composition

Fit, Tolerance, Deviation, Allowance

➢ Fit is the relationship that exists between two mating parts, a hole and shaft, with respect to their dimensional differences before assembly.

➢ An intentional difference between the hole dimensions and shaft dimensions for any type of fit is called Allowance

➢ Tolerance is the difference between the upper limit and lower limit of daviation.

➢ Upper Deviation is the algebraic difference between the maximum size and the basic size.

➢ Lower Deviation is the algebraic difference between the minimum size and the basic size.

· The system said to be bilateral tolerance if the Tolerance is in two direction

· The notation 70H6/ g5 means – Basic size is 70mm and tolerance grade of hole is 6 and shaft is 5

A welding rectifier is used to convert A.C welding supply into a D.C. supply

✓ For carbon steel, the flux is not using during welding.

✓ Flash back and back fire occurs in Gas welding

Most suitable cutting flame is oxidizing flame

✓ An undesirable property of is high boiling point

Density is the mass per unit volume

Relative density, or specific gravity, is the ratio of the density of a substance to the density of a given reference material.

Velocity = Displacement/Time (V=D/t)

Velocity is a vector expression of the displacement that an object or particle undergoes with respect to time (m/s)

Weight is the measure of the intensity of the force imposed on the object by the local gravitational field.

Mass is a measure of the amount of matter in an object.

Specific weight (also known as the unit weight) is the weight per unit volume of a material.

One litter of liquid weight 8N. The specific weight will be 8000N/m3

Specific volume is defined as the volume per unit mass

Pressure at a point is the force per unit area

The viscosity of a fluid is a measure of its resistance to deformation at a given rate.

Momentum of a body is given by Mass x Velocity

1 Metric horse power = 736 watts

1 Mechanical horse power = 746 watts

1 stoke =

Hooke’s law

Hooke’s law states that for material loaded within elastic limits, the stress is proportional to strain, produced by stress.

Fleming's law

For electric motors For electric generator

Planck's law describes the spectral density of electromagnetic radiation emitted by a black body in thermal equilibrium at a given

temperature (T), when there is no net flow of matter or energy between the body and its environment.

Bernoulli's principle states that an increase in the speed of a fluid occurs simultaneously with a decrease in pressure or a decrease in the fluid's potential energy.

Working of orifice meter is based on Bernoulli's theorem

A sprayer make use of Bernoulli's principle

Archimedes' principle the buoyant force is equal to the weight of the displaced water

Euler’s law

Fluid mechanic deals with the behavior of the Liquids and gases

The unit of surface tension in SI unit is N/m

✓ The pitch of the stair should be limited to 30° - 40°

✓ The maximum frictional force, when a body just begins to slide is called Limiting friction

The total motion possessed by a body, is called Momentum

If the momentum of a given particle is doubled, then its kinetic energy will be quadrupled

Torque

if = 90° - Torque = r * F (sin 90 = 1)

Escape velocity of Earth = 11.2 km/s

Moment of inertia of a circular section about its diameter (d) is:

Valves

Pearlite is a combination of Ferrite and cementite (Fe3C)

A standard-gauge railway is a railway with a track gauge of 1,435 mm

Drafting Solutions

Drafting Solutions Find alternative Beam

Find alternative Beam Find alternative Channel

Find alternative Channel

No comments:

Post a Comment